Your Problem is Our Business

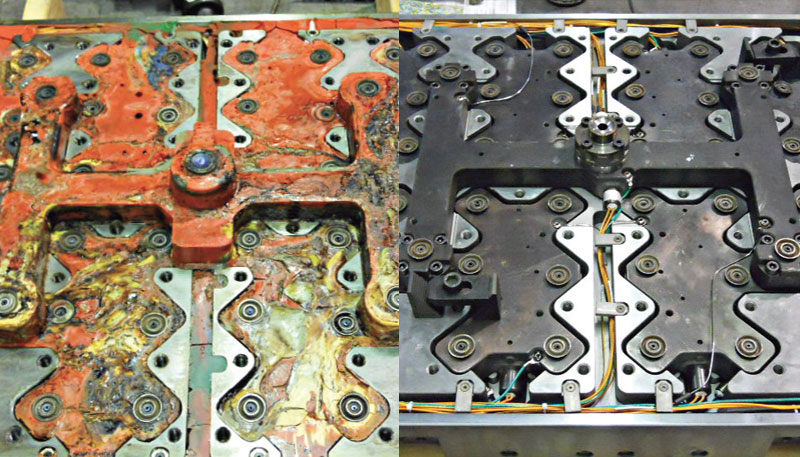

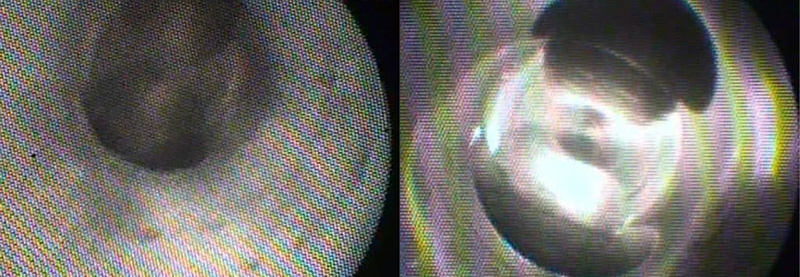

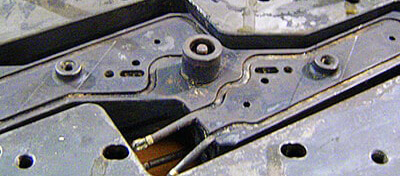

Thermal-Tech Systems has accomplished a lot over the past 32 years. We are today’s hot runner and manifold cleaning problem solving supplier of choice. With expanded hot runner parts and high functionality hot runner control systems, for today and future manufacturing technology. We rebuild, troubleshoot and bore scope inspect entire manifold cleaning and plastic injection molding hot runner systems.We work on all brands of systems specializing in repair and rebuild of all types of hot runner systems such as, Husky, Mold Masters, PSG, and StackTeck. Our capabilities expand into all hot tip and valve gate plastic injection molding hot runner systems, and include cold halves, cavity inspection and repair or rebuild. Our turnkey operation places your manifold and plastic injection molding hot runner system back to you tested and ready for production.

Established in 1986 in Illinois we began as a distributor of Slide, rust preventative, mold release cleaners, and purging compounds for the plastic injection molding industry. We now also specialize in hot runner components, including heaters, thermocouples, tips, nozzles and many other hot runner and manifold parts. Our team has seasoned employees with hot runner and manifold cleaning with an average of 30+ years of experience in the plastic injection molding industry.

If you don’t want it to stick, make it Slide. Mold releases, mold cleaners, lubricants, rust preventives, purging compounds. We have been the #1 distributor for Slide since 1986.

If you don’t want it to stick, make it Slide. Mold releases, mold cleaners, lubricants, rust preventives, purging compounds. We have been the #1 distributor for Slide since 1986.